Neutron Mirror Fabrication System

Neutron Mirror Fabrication Facility

(Ion Beam Deposition and Vacuum Evaporation for large neutron mirrors)

The neutron mirror fabrication facility consists of two deposition instrument, Ion Beam Sputtering deposition (KUR-IBS) and Large Vacuum Evaporation (LVE) instruments. The both instruments are optimized for production of neutron multilayer mirrors

A Multilayer mirror is one of the most useful devices for slow neutron experiments. Multilayer mirrors and supermirrors are applied to neutron optical devices, such as neutron guide tube and foucsing mirror.

The multilayer mirror consists of alternating layers of two materials with different potential energies for the neutron. It has artificial lattice spacing (d-spacing) and gives one-dimensional optical potentials for a neutron beam. Supermirror is a stack of multilayers with gradually increasing value of the d-spacing. A multilayers with small d-spacing and supermirror with large-m is desirable to enlarge utilization efficiency for neutron scattering experiments. Recently we succeeded in fabricating large-m(m=7)NiC/Ti using ion beam sputtering technique. The KUR-IBS is used for high quality mirror fabrication. It has ion sources for sputtering and assist. The maximum sample size is 480 mm in diameter and the number of target is 6. The LVE instrument is used for large size mirrors. Eight mirrors of 110×350mm² can be fabricated at once.

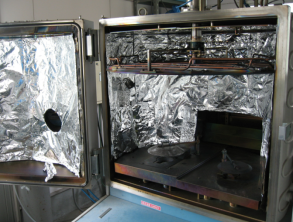

Fig. 1. Photograph of KUR-IBS (Ion Beam Sputtering deposition) instrument. |

Fig. 2. Photograph of LVE (Large Vacuum Evaporation) instrument. |